Process Equipment's

Autoclaves

Regular Steam Autoclave- RSA

RSA are particularly designed for sterilization by steam of heat-resistant and moisture-stable materials such as metals parts, plastics, rubbers, filters, liquid in sealed or vented containers, Clothes, etc.

Flexible: It offers the possibility to sterilize packed or unpacked solids and liquids in sealed or vented containers. The high efficient built in steam generator allow to reduce the foot print of the machine.

Main Features:

Regular Steam Autoclave- RSA

RSA are particularly designed for sterilization by steam of heat-resistant and moisture-stable materials such as metals parts, plastics, rubbers, filters, liquid in sealed or vented containers, Clothes, etc.

Flexible: It offers the possibility to sterilize packed or unpacked solids and liquids in sealed or vented containers. The high efficient built in steam generator allow to reduce the foot print of the machine.

Main Features:

- Large variety of chamber sizes.

- Easy assembling and disassembling (reduced direct labor).

- Possibility of loading any shape/sizes of products.

- Optimization of all process phases.

- Uniform temperature distribution (+0.10C).

- Perfect air removal.

- Low residual humidity.

Component Washing machine

Utensil and Container Washers-UCW

UCW is particularly designed for the complete cleaning of the surfaces of utensils, glassware, filling machine parts, IBC containers, etc.

Flexible: that it can be used for the process of large variety of products such as minor items, glassware, needles, tubes, drums, clamps, bottles, tanks, collectors, trays and combined materials with the same proven results.

Rotating Spray Nozzles concept: Pressurized water and intensive spray action by rotating nozzles. Low (2-3 bar) and high (40-80 bar) water pressure is available. Nozzles completely made of 316L stainless steel with no threads (GMP) type.

Spray nozzles of static type for cleaning of external surfaces and of telescopic type for the internal cleaning of large containers (IBC tanks, bins, etc.)

Utensil and Container Washers-UCW

UCW is particularly designed for the complete cleaning of the surfaces of utensils, glassware, filling machine parts, IBC containers, etc.

Flexible: that it can be used for the process of large variety of products such as minor items, glassware, needles, tubes, drums, clamps, bottles, tanks, collectors, trays and combined materials with the same proven results.

Rotating Spray Nozzles concept: Pressurized water and intensive spray action by rotating nozzles. Low (2-3 bar) and high (40-80 bar) water pressure is available. Nozzles completely made of 316L stainless steel with no threads (GMP) type.

Spray nozzles of static type for cleaning of external surfaces and of telescopic type for the internal cleaning of large containers (IBC tanks, bins, etc.)

Main Features:

- Reducing of excessive accumulation of products during the process.

- Elimination of mechanical strains.

- No particle generation due to friction and abrasion.

- Enhanced surfaces exposure at process fluids.

- Possibility of loading different patters/sizes of products in one batch (combo-loads).

- Visual and digital (by cameras) check of line- clearance and cleaning.

- Uniform cleaning.

- Uniform heat distribution.

- Full automatic control of water conductivity, TOC and Ph.

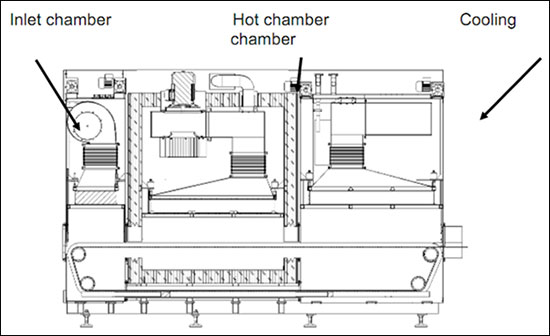

Dry Heat Sterilizer-DHS

Dry Heat Sterilizer � DHS

DHS is particularly designed for sterilization and depyrogenation by hot air in class 100 (ISO 5) of empty glass containers such as vials, ampoules, bottles and stainless steel parts.

Flexible: it can be used for sterilization, depyrogeneation and drying of any solid material resistant to dry heat. While the product drying may be run at temperature adjustable between 500C and 1200C.

Main Features:

Dry Heat Sterilizer � DHS

DHS is particularly designed for sterilization and depyrogenation by hot air in class 100 (ISO 5) of empty glass containers such as vials, ampoules, bottles and stainless steel parts.

Flexible: it can be used for sterilization, depyrogeneation and drying of any solid material resistant to dry heat. While the product drying may be run at temperature adjustable between 500C and 1200C.

Main Features:

- Reduced foot print.

- Large variety of chamber sizes.

- Easy assembling and disassembling (reduced direct labor).

- Possibility of loading any shape/sizes of products.

- Optimization of all process phases.

- Uniform temperature distribution (+10C).

- Built-in air handling units (air intake and air exhaust with HEPA 14 filters).

- Built-in air recycling wall with HEPA 14 filters.

- Built-in air heating unit.

- Built- air cooling unit.

Tray Dryer-TD

TD are particularly designed for drying solid materials such as powders, fine granulates, machines parts, filters, etc.

Flexible: it can be used for drying of any kind of solid material resistant to dry heat. The drying temperature is adjusted between 70�C and 120�C with a temperature deviation of +20C. product cooling up to room temperature. (250C)

TD are particularly designed for drying solid materials such as powders, fine granulates, machines parts, filters, etc.

Flexible: it can be used for drying of any kind of solid material resistant to dry heat. The drying temperature is adjusted between 70�C and 120�C with a temperature deviation of +20C. product cooling up to room temperature. (250C)

Main Features:

- Large variety of chamber sizes.

- Easy assembly and disassembly (reduced direct labor).

- Possibility of loading any shape/sizes of products.

- Optimization of all process phases.

- Uniform temperature distribution (+20C).

- Built-in air handling units (air intake and air exhaust with HEPA 14 filters).

- Built-in air recycling system with recycling wall with HEPA filters (optional).

- Built-in air heating unit.

- Built- air cooling unit.

- Temperature and humidity control.

Terminal Sterilizer -TS

TS are particularly designed for terminal sterilization of liquids contained in sealed containers such as flexible bags, glass bottles, BFS bottles, syringes, cartridges, ampoules, etc.

Flexible: it can be used for sterilization any kind container for liquids. From a small pre-filled syringe/cartridge up to large bag/bottle made of glass, PVC, non-PVC, PET, PTFE, Polypropylene, Polythene, etc. Flexibility guaranteed by an automatic differential pressure compensation based on product probes (RTD) temperature measurement (?T).

TS are particularly designed for terminal sterilization of liquids contained in sealed containers such as flexible bags, glass bottles, BFS bottles, syringes, cartridges, ampoules, etc.

Flexible: it can be used for sterilization any kind container for liquids. From a small pre-filled syringe/cartridge up to large bag/bottle made of glass, PVC, non-PVC, PET, PTFE, Polypropylene, Polythene, etc. Flexibility guaranteed by an automatic differential pressure compensation based on product probes (RTD) temperature measurement (?T).

Main Features:

- Reduced foot print.

- Large variety of chamber sizes.

- Easy assembly and disassembling (reduced direct labor).

- Possibility of loading any shape/sizes of products.

- Optimization of all process phases.

- Uniform temperature distribution (�5�C).

- System to prevent any kind of deformation, damaging and bad coloring of the plastic containers.

- Possibility to have two solutions/typology of process. Air + Steam Mixture and Overheated Water.

Liquid And Lyophilised Product Vial Filling Line

- Vial Washing Machine

- Hot Air Sterilization & Depyrogenation Tunnel

- Monoblock Vial Liquid Filling & Stoppering

- Aluminium Cap Sealing Machine

Vial Washing Machine

- Vials washing machine is designed with individual water and air cleaning station as cGMP standards.

- The machine ultrasonically cleans (Option).Pressurised spray washes and rinses the interior and exterior of vials with Liquid Media and blows compressed air into and over the exterior of vials.

- Siliconization is also possible and multiple container infeed and exit configuration are available.Automatic Guard opening.

- CIP/SIP of the Piping System.Minimum Dead Leg in the line.

Hot Air Sterilization & Depyrogenation Tunnel

The hot Air Sterilization & Depyrogenation laminar air flow tunnels sterilize and Depyrogenates glass vials. Unidirectional Laminar air flow preheats, Depyrogenates and cools the vials in an ISO 5 environment attaining a 3 log bio-burden reduction of Endotoxins.

The hot Air Sterilization & Depyrogenation laminar air flow tunnels sterilize and Depyrogenates glass vials. Unidirectional Laminar air flow preheats, Depyrogenates and cools the vials in an ISO 5 environment attaining a 3 log bio-burden reduction of Endotoxins.

- Auto balancing of zones.

- Velocity control and pressure Balancing.

- Sleep and wake functionality, recording devices and multiple infeed and exit configuration are available.

- Automatic Gate opening.

- Sterilization of Cooling Zone.

- Chilling Coil.

- Auto Unloading of Last Vials in Filling Room.

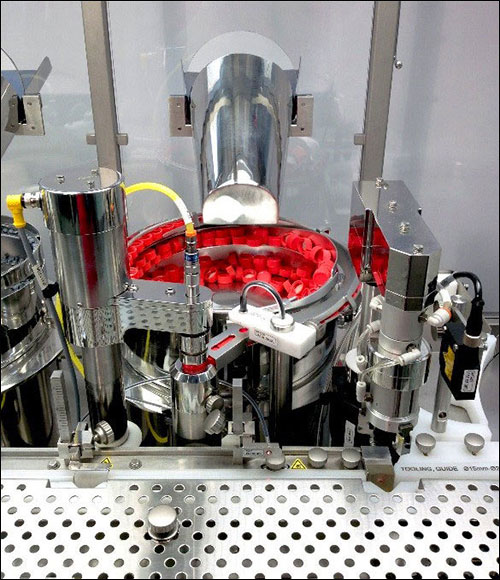

Monoblock Vial Liquid Filling & Stoppering

- The Liquid Filling & Stoppering Machine is Compact Designed Linear Monoblock suitable for widerange of Glass & Plastic Vials.

- Vial Transfer conveyors are designed to handle different Vials without change over.

- Different Filling methods available such as SS Rotary Pumps, Ceramic Pumps & Diaphragm Pumps.

- Also peristaltic Pumps are available.

- Suitable to handle Cytotoxic Products.

- Statistical Check weighing & 100% Check Weighing.

- Experienced designing, manufacturing & Integration of Containments such as VLAF, HLAF oRABS, cRABS & Isolators.

Aluminium Cap Sealing Machine

- The Aluminium Cap Sealing Machine is designed with intermittent motion / continuous motion.

- The intermittent motion RCS alu-crimp caps vials around an indexing star wheel.

- The high speed continuous motion RPC crimps vials around a turret with upto 10 heads.

- Rejection System for Improper & absent Seal.

- Positive Vial Control.

- Vial Height Compensation.

- Adjustable Sealing Pressure.

Ampoule Filling Line & Combo Ampoule

- Ampoule & Vial Washing Machine

- Sterilization & Depyrogenation Tunnel

- Ampoule Filling & Sealing Machine

Ampoule & Vial Washing Machine

- Customized layout in accordance to special enduser's demands.

- Containers feeding from unscrambling units, rotary or bi-flow tables, depending on process and layout configuration.

- Inclined infeed module with ultrasonic bath unit.

- Detergent storage tank with automatic dispensing unit.

- Recycled water tank with temperature control.

- Siliconization station.

- Filtering unit on each liquid flow path.

- Fully sterilizable pumps.

- Vapour extraction unit.

- Automatic draining and drying stations.

- CIP/SIP functionalities.

- Remote assistance.

- Printer and SCDA Interface for production data recording and management.

- Documentation packages for complete system validation.

- Direct connection to sterilization tunnel.

Sterilization & Depyrogenation Tunnel

- Inline connection to upstream and downstream equipment.

- Additional cooling chamber.

- Sterilizable cooling chamber.

- Particle measuring inside the chamber.

- Continuous airflow measuring system.

- Automatic air pressure balance inside the tunnel for consistent positive pressure to avoid air back flow.

- Air speed monitoring and automatic adjustment by means of anemometric system in all chambers.

- Automatic vial discharge at batch end.

- Remote assistance.

- Printer and SCADA interface for the production data recording and management.

- Documentation packages for complete system validation.

Ampoule Filling & Sealing Machine

The AFM series machines are designed to process both closed and open ampoules. Developed to meet current pharmaceutical industry requirements, and to address the needs of the enduser, they are suitable both for liquid parenterals and products that must undergo the lyophilisation process.Their extremely slim design reduces expensive classified area space requirements, though within a conventional clean room, or with other containment systems such as RABS or isolators. It also allows different layout configurations and center of the room or wall installation.

The AFM series machines are designed to process both closed and open ampoules. Developed to meet current pharmaceutical industry requirements, and to address the needs of the enduser, they are suitable both for liquid parenterals and products that must undergo the lyophilisation process.Their extremely slim design reduces expensive classified area space requirements, though within a conventional clean room, or with other containment systems such as RABS or isolators. It also allows different layout configurations and center of the room or wall installation.

The AFM Series can work as a standalone unit or connected in line with sterilization tunnel (open ampoules). It can be equipped with up to 12 filling nozzles offering a productivity ranging from 30-600 ampoule/minute.

- Customized layout in accordance to special enduser's demands.

- Inline connection to upstream and downstream equipment.

- Wall installation.

- Containers feeding from unscrambling units, rotary or bi-flow tables (depending on process and layout configuration).

- Pre-heating group to process closed ampoules.

- Intermediate tank with level control by means on weighing cell.

- Statistical or 100% IPC.

- Nitrogen purging group before, during and after filling operations.

- Descaled and passivated filling circuit.

- Vials stoppering and sealing/ crimping heads (COMBI version).

- Closures presence control and automatic rejection systems.

- CIP/SIP functionalities.

- Remote assistance.

- Printer and SCADA interface for production data recording and management.

- Integration with conventional LAF units or RABS.

- Preparation for isolation technology.

- Documentation packages for complete system validation.

Pre-Filled Syringe Filling Line

Auto Tyvek Removal

Filling & Stoppering Machine

The SYFILL series of fiiling and stoppering machines have been specially designed to process already sterile nested containers, such as syringes, cartridges, and vials.Developed to meet current pharmaceutical industry standards and requirements, the SYFILL Series has a particularly compact design that reeduces the space taken in sterile room.

The SYFILL series of fiiling and stoppering machines have been specially designed to process already sterile nested containers, such as syringes, cartridges, and vials.Developed to meet current pharmaceutical industry standards and requirements, the SYFILL Series has a particularly compact design that reeduces the space taken in sterile room.

SYFILL machines can be intergarated with conventinal LAF systems, RABS or isolators. They can also be configured for wall installation.The same machine can use 1-10 filling nozzles while keeping the same frame and design in order to cover a wide range of productivity (30-500 containers/minute).

Cartridge Filling Line

Washing Machine

- Customized layout in accordance to special end user's demands.

- Containers feeding from unscrambling units, rotary or bi-flow tables, depending on process and layout configuration.

- Inclined infeed module with ultrasonic bath unit.

- Detergent storage tank with automatic dispensing unit.

- Recycled water tank with temperature control.

- Siliconization station.

- Filtering unit on each liquid flow path.

- Fully sterilizable pumps.

- Vapour extraction unit.

- Automatic draining and drying stations.

- CIP/SIP functionalities.

- Remote assistance.

- Printer and SCDA Interface for production data recording and management.

- Documentation packages for complete system validation.

- Direct connection to sterilization tunnel.

Sterilization & Depyrogenation Tunnel

- Inline connection to upstream and downstream equipment.

- Additional cooling chamber.

- Sterilizable cooling chamber.

- Particle measuring inside the chamber.

- Continuous airflow measuring system.

- Automatic air pressure balance inside the tunnel for consistent positive pressure to avoid air back flow.

- Air speed monitoring and automatic adjustment by means of anemometric system in all chambers.

- Automatic vial discharge at batch end.

- Remote assistance.

- Printer and SCADA interface for the production data recording and management.

- Documentation packages for complete system validation.

For Filling & Stoppering

The SYFILL series of fiiling and stoppering machines have been specially designed to process already sterile nested containers, such as syringes, cartridges, and vials.Developed to meet current pharmaceutical industry standards and requirements, the SYFILL Series has a particularly compact design that reeduces the space taken in sterile room.

The SYFILL series of fiiling and stoppering machines have been specially designed to process already sterile nested containers, such as syringes, cartridges, and vials.Developed to meet current pharmaceutical industry standards and requirements, the SYFILL Series has a particularly compact design that reeduces the space taken in sterile room.

SYFILL machines can be intergarated with conventinal LAF systems, RABS or isolators. They can also be configured for wall installation.

The same machine can use 1-10 filling nozzles while keeping the same frame and design in order to cover a wide range of productivity (30-500 containers/minute).

R & D Application Machine

Manual Powder Filling Machine

The M&O Perry Powder filler are designed using the ACCOFIL Technology, a patented technology in 1948.Thanks to our Experience of more than 60 years, which makes our Machines one of the best in World.

The M&O Perry Powder filler are designed using the ACCOFIL Technology, a patented technology in 1948.Thanks to our Experience of more than 60 years, which makes our Machines one of the best in World.

- It is designed to cover range from 2mg to 1000gm per dose.

- Vacuum pressure filling principal..

- CGMP compliance.

- Lab Application.

Single Head Liquid Filling Unit

This is single head filling system designed to fill from 0.001ml to 150ml with different set of syringes.It is designed to adjust pump volume by weight. It is provided with Quick fitting of the pump with the patented system KLYX. It is 21CFR part 11 Compliant.

This is single head filling system designed to fill from 0.001ml to 150ml with different set of syringes.It is designed to adjust pump volume by weight. It is provided with Quick fitting of the pump with the patented system KLYX. It is 21CFR part 11 Compliant.

- Compact size.

- Closed loop positioning system.

- Filling volume from 0.001ml to 150ml.

- Quick fitting of the pumps with the patented system KLYX.

- CFR 21 Part 11 Compliance.

- Applicable for small bath or clinical trail.

Autoclave

cGLP Steam Sterilizer � Type Nebula

Nebula are designed for sterilization by saturated steam of heat- resistant and moisture-stable materials such as metal parts, plastic and rubber components, liquid in sealed or vented containers, clothes, etc.

cGLP Steam Sterilizer � Type Nebula

Nebula are designed for sterilization by saturated steam of heat- resistant and moisture-stable materials such as metal parts, plastic and rubber components, liquid in sealed or vented containers, clothes, etc.

Flexible: it offers the possibility to sterilize packed or unpacked solids and liquids in sealed or vented containers. The high efficient built in steam generator allow to reduce the footprint of the machine.

Main Features:

- Large variety of chamber sizes.

- Easy assembling and disassembling (reduced direct labor).

- Possibility of loading any shape/sizes of products.

- Optimization of all process phases.

- Uniform temperature distribution (�1�C).

- Perfect air removal.

- Low residual humidity.

Components Washing machine

cGLP Glassware washer � Type AQUA.

AQUA is particularly designed for process cleaning, dis-infection and decontamination of materials used in research laboratories such as glassware, metal parts, plastic and rubber components, etc.Flexible: that it can be used for the process of large variety of products such as minor items, glassware, needles, tubes, drums, clamps, bottles, tanks, collectors, trays and combined materials with the same proven results.Rotating Spray Nozzles concept: Pressurized water and intensive spray action by rotating nozzles. Low (2-3 bar) and high (40-80 bar) water pressure is available. Nozzles completely made of 316L stainless steel with no threads (GMP) type. Spray nozzles of static type for cleaning of external surfaces and of telescopic type for the internal cleaning of large containers (IBC tanks, bins, etc.)

Main Features:

- Reducing of excessive accumulation of products during the process.

- Elimination of mechanical strains.

- No particle generation due to friction and abrasion.

- Enhanced surfaces exposure at process fluids.

- Possibility of loading different patters/sizes of products in one batch (combo-loads).

- Visual and digital (by cameras) check of line- clearance and cleaning.

- Uniform cleaning.

- Uniform heat distribution.

- Full automatic control of water conductivity, TOC and Ph.

For Dry Syrup Filling Line

Air Jet Cleaning Machine

- Customized layout in accordance to special end user�s demands.

- Containers feeding from unscrambling units, rotary or bi-flow tables, depending on process and layout configuration.

- Inclined infeed module with ultrasonic bath unit.

- Detergent storage tank with automatic dispensing unit.

- Recycled water tank with temperature control.

- Siliconization station.

- Filtering unit on each liquid flow path.

- Fully sterilizable pumps.

- Vapour extraction unit.

- Automatic draining and drying stations.

- CIP/SIP functionalities.

- Remote assistance.

- Printer and SCDA Interface for production data recording and management.

- Documentation packages for complete system validation.

- Direct connection to sterilization tunnel.

Powder Filling Machine

The M & O Perry Powder filler are designed using the ACCOFIL Technology, a patented technology in 1948.Thanks to our Experience of more than 60 years, which makes our Machines one of the best in World. Macro dose Powder Filling machines accurately dose large fills of powder into Glass and plastic Bottles with Principal of ACCOFIL. An optional capping turret applies ROPP, snap-on, screw type or tamper proof caps onto bottles. Typical applications includes ORAL ANTIBIOTICS AND BABY POWDER into glass and plastic bottles and ASPRIN IN POUCHES.

The M & O Perry Powder filler are designed using the ACCOFIL Technology, a patented technology in 1948.Thanks to our Experience of more than 60 years, which makes our Machines one of the best in World. Macro dose Powder Filling machines accurately dose large fills of powder into Glass and plastic Bottles with Principal of ACCOFIL. An optional capping turret applies ROPP, snap-on, screw type or tamper proof caps onto bottles. Typical applications includes ORAL ANTIBIOTICS AND BABY POWDER into glass and plastic bottles and ASPRIN IN POUCHES.

- Fill weights from 3gms to 200gms can be handled.

- A precise filling accuracy with most of the powders.

- Motorised Head-Lift Assembly.

- Speed upto 300 Bottles per Min.

- Statistical / 100% checkweighing.

- Sugar based products can be easily handled.

Capping

Components Washing machine

cGLP Glassware washer � Type AQUA.

AQUA is particularly designed for process cleaning, dis-infection and decontamination of materials used in research laboratories such as glassware, metal parts, plastic and rubber components, etc.Flexible: that it can be used for the process of large variety of products such as minor items, glassware, needles, tubes, drums, clamps, bottles, tanks, collectors, trays and combined materials with the same proven results.Rotating Spray Nozzles concept: Pressurized water and intensive spray action by rotating nozzles. Low (2-3 bar) and high (40-80 bar) water pressure is available. Nozzles completely made of 316L stainless steel with no threads (GMP) type. Spray nozzles of static type for cleaning of external surfaces and of telescopic type for the internal cleaning of large containers (IBC tanks, bins, etc.)

Main Features:

- Reducing of excessive accumulation of products during the process.

- Elimination of mechanical strains.

- No particle generation due to friction and abrasion.

- Enhanced surfaces exposure at process fluids.

- Possibility of loading different patters/sizes of products in one batch (combo-loads).

- Visual and digital (by cameras) check of line- clearance and cleaning.

- Uniform cleaning.

- Uniform heat distribution.

- Full automatic control of water conductivity, TOC and Ph.

Rotary Filling Pumps For Liquids

SS Rotary Filling Pumps

SPC, a 100 Years old company, is a manufacturer of Tailor Made devices such as Rotary Piston Pumps, Needles fo⇓r Filling Machines & Washing Machines.The word SPC is synonymous to Your precision partner for liquid filling The various industry we serve are pharmaceuticals, machinery manufacturer of sterile equipments (oem s), cosmetics, biotech & the food industry.

SPC, a 100 Years old company, is a manufacturer of Tailor Made devices such as Rotary Piston Pumps, Needles fo⇓r Filling Machines & Washing Machines.The word SPC is synonymous to Your precision partner for liquid filling The various industry we serve are pharmaceuticals, machinery manufacturer of sterile equipments (oem s), cosmetics, biotech & the food industry.

- SS316L Seal- Less volumetric piston Pumps for filling liquids.

- Variant designed Pumps are available based on various Makes of Filling Machine.

- PVDCrN,a special coating providing a high level of mechanical resistance for special liquids.

- Traceability of pumps for future needs.

- Individual testing of pumps using Water tightness test.

- Pumps for CIP/SIP version is also available.

Ceramic Rotary Filling Pumps

- Custom designed.

- Monobloc stainless steel or ceramic design, to meet pharmaceutical requirements.

- 316L Stainless steel.

- ZrO2 + Y2O3 Yttria-stabilized zirconia (white), ZrO2 + MgO - stabilized with Magnesia (white or yellow), Al2O3 Alumina (>99.5%).

- Hard chrome and PVD CrN (only with 316L) coating (providing a high level of mechanical resistance).

- CIP/SIP version available.

- Water tightness-test prior to shipment (Flotest�).

- CGMP compliant.

- Decontamination and passivation.

- Traceability documentation supplied.

Washing & Filling Needles

- SS316L Stainless Steel design to meet pharmaceutical requirements.

- Internal & External Electrolytic Polishing (On Request) for an Optimal Surface(Ra<0.4).

- Monoblock design and/ welded design (Laser or TIG).

- Decontamination & Passivation.

- All kind of tips available (Simple-Eye,Anti-Drop,Limited Tip,Spherical Tip).

PP Injection Stretch Blow Moulding & Filing Line(ISBM)

PP Injection Strektch Blow Molding Filling Line

ISBM technology is the modern manufacturing trend for LVP solution.It comprises of complete processing lines for both for IV bottles and bags. [Advantages of ISBM].

Line Costs of ISBM system is lower than the cost of BFS system.

Costs For Bottle Production In manners of raw materials consumption,the cost for producing one 500ml bottle with the ISBM system is lower with about 35% than producing it with the BFS system.

Wasted Raw Materials-With the ISBM system the wasted raw material for the production of one 500 ml PP bottle is equal to 0%. It is another point in advantage of ISBM because of production costs optimization.

Optical Inspection-The bottles produced with the ISBM system have high levels of transparency, so the customer can obtain high levels of accuracy in case of optical inspection: this means better results and higher accuracy in case of optical inspection for the ISBM bottles.

Hours of Production-This system is suitable to work in continuous from 8 hours up to 24 hours per day without any problem.

Interface And Line Simplicity-The system have a very simple interface and way to manage so there is no need to high qualified operator to supervise on it.

After Bottle Forming-In the system there is a possibility to blow the bottles inside with ionized air to be sure that there is no residual or any plastic particles inside the bottle: better accuracy in product purity and cleanness.

Bottles Sterilization-The PP bottles formed by ISBM system it can be sterilized in autoclave at high temperature;up to 121degree without losing the form and remaining identical.

Possible Closures

With this system there are different type of caps which can be applied on the final bottle:

- Sealed EuroCap.

- Sealed Irrigation cap.

- Screw cap.

- Stopper and Aluminum cap.

Bottle design-With this system the bottle design can be changed and personalized at any time the customer need,it request only a change in the bottle moulds.

Change Format-To change he bottle format (ex: from 500 ml to 1000 ml),it takes around 45 min for the complete line.

CIP/SIP Cycle-The estimated time to prepare the filling machine to a CIP/SIP cycle is around 5 min, and additional 25 min to do the cycle, automatically without the need to use any tool by the supervising operator.

Speed-It can reach capacities from 500 BpH up to 24000 BpH, depending on the customer request,reaching higher speed than a BFS system.

FDA-ISBM lines actually on production are already FDA approved. This allows products export worldwide,including USA and Japan.

Plastic Bottle Filling Line

- Low cost for molding tools and dies.

- Optimized design and structure to allow easy cleaning of all working surfaces, easy acess for maintenance operations, absence of dead zones and corners.

- Cost savings due to zero material waste.

- Lower energy consumption.

- Reduced line startup time.

- Production of recyclable packaging components.

- The containers produced have a high level of transparency, which makes them more suitable for automatic optical inspection.

- Final sterilization process in autoclave.

- Simple operation, quick changeovers, and low maintenance.

- All product contact parts are made of stainless stell AISI with finishing ranging from 0.4 � 0.8 Ra, or with FDA approved materials.

- Flexibility over a wide range of filling volumes and container shapes, from 50 -1000 ml.

- Possibility to adapt different dosing systems such as mass flow meters and time- pressure dosing.

- High production rates and line efficiency.

- User friendly touchscreen operator interface (HMI).

- CFR 21 part 11 compliant.

Camera Inspection Machine For Container

For Vial, Ampoule & Cartridges

This Machine can process Ampoules, Vials and Cartridges filled with sterile products.These are fully automated inspection machines represents the ideal solution to comply GMP requirements and to ensure that injectable products are essentially free of contamination.In standard configuration each containers are inspected at least three times for particles. If deemed necessary a fourth station can also be installed.

This Machine can process Ampoules, Vials and Cartridges filled with sterile products.These are fully automated inspection machines represents the ideal solution to comply GMP requirements and to ensure that injectable products are essentially free of contamination.In standard configuration each containers are inspected at least three times for particles. If deemed necessary a fourth station can also be installed.

- Patented pneumatic Gripper design for holding containers, eliminates the bottom support smooth handling of containers with fragile tips.

- Seldom breakage of container that may happen, will facilitate the cleaning process due to no Support in the bottom of the container.

- Heavy Particle inspection on request.

- Brushless motors for rotation ensure complete optimization of all spin parameters according to the product size and the inspection station.

- Powerful microprocessors and efficient software offers high speed operation.

- Hi-tech analysis of physical parameters and state of the art sensors make highly reliable results and drastic reduction of acquisition errors.

- High-resolution CCD cameras facilitates high sensitivity with smaller particles.

- Advanced brushless motors reduces power consumption.

- Leak test can be provided on request.

- Cosmetic check station can be provided on request.

For Syringes

This Machine can process Ampoules, Vials and Cartridges filled with sterile products.These are fully automated inspection machines represents the ideal solution to comply GMP requirements and to ensure that injectable products are essentially free of contamination.In standard configuration each containers are inspected at least three times for particles. If deemed necessary a fourth station can also be installed.

This Machine can process Ampoules, Vials and Cartridges filled with sterile products.These are fully automated inspection machines represents the ideal solution to comply GMP requirements and to ensure that injectable products are essentially free of contamination.In standard configuration each containers are inspected at least three times for particles. If deemed necessary a fourth station can also be installed.

- Patented pneumatic Gripper design for holding containers, eliminates the bottom support smooth handling of containers with fragile tips.

- Seldom breakage of container that may happen, will facilitate the cleaning process due to no Support in the bottom of the container.

- Heavy Particle inspection on request.

- Brushless motors for rotation ensure complete optimization of all spin parameters according to the product size and the inspection station.

- Powerful microprocessors and efficient software offers high speed operation.

- Hi-tech analysis of physical parameters and state of the art sensors make highly reliable results and drastic reduction of acquisition errors.

- High-resolution CCD cameras facilitates high sensitivity with smaller particles.

- Advanced brushless motors reduces power consumption.

- Leak test can be provided on request.

- Cosmetic check station can be provided on request.

For Glass And Plastic Bottles

When processing containers immediately after autoclaving, there might be the need to eliminate residual water or moisture and so a special drying module can be added to the machine. Containers are externally dried to finally undergo leak testing and or particulate and cosmetic inspection for drying module on request.

When processing containers immediately after autoclaving, there might be the need to eliminate residual water or moisture and so a special drying module can be added to the machine. Containers are externally dried to finally undergo leak testing and or particulate and cosmetic inspection for drying module on request.

- Patented pneumatic Gripper design for holding containers, eliminates the bottom support smooth handling of containers with fragile tips.

- Seldom breakage of container that may happen, will facilitate the cleaning process due to no Support in the bottom of the container.

- Heavy Particle inspection on request.

- Brushless motors for rotation ensure complete optimization of all spin parameters according to the product size and the inspection station.

- Powerful microprocessors and efficient software offers high speed operation.

- Hi-tech analysis of physical parameters and state of the art sensors make highly reliable results and drastic reduction of acquisition errors.

- High-resolution CCD cameras facilitates high sensitivity with smaller particles.

- Advanced brushless motors reduces power consumption.

- Leak test can be provided on request.

- Cosmetic check station can be provided on request.

Surface Disinfection using H2O2, Dosy Mist ⇓

DOSYMIST The New Generation of H2O2 Generation System

Solidfog offers you Simple,Reliable,Economical and Easy to validate decontamination system with H2O2.

Solidfog offers you Simple,Reliable,Economical and Easy to validate decontamination system with H2O2.

- Simple: Compact design, reduced size, mobile and easy to handle (plug-and-play).

- Reliable: Calibration certificate of components, Siemens PLC, control and self-diagnose of working parameters. IQ/OQ complete documentation.

- Economical: High quality for a fair price, use of non-proprietary biocide (H2O2 12%), better and wider materials compatibility.

- Ease Of Validation: Great dispersion capacity (up to 200 m3 volume), very high efficiency (up to 6-log) and capable of monitoring and recording data for cycle validation.

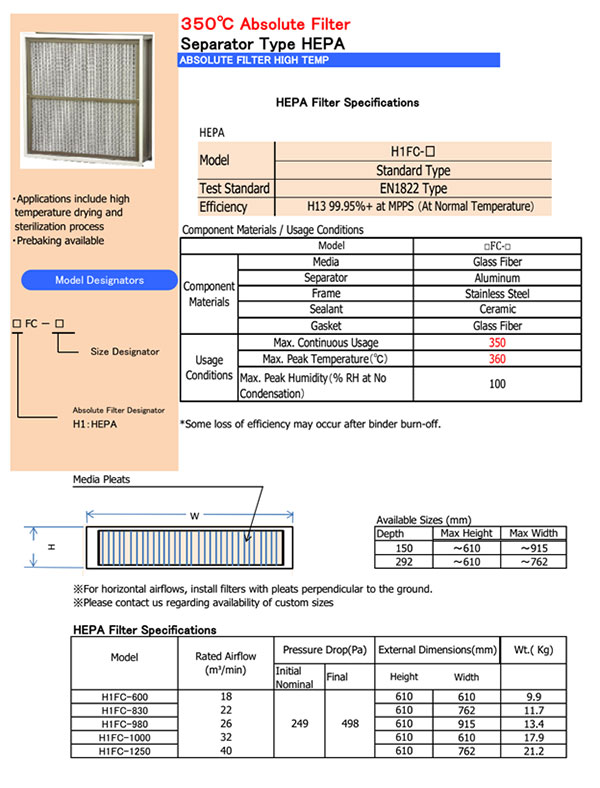

High Temperature HEPA H13 Filters for 350OC Application ⇓

High Temperature Filter Selection Guide

Cambridge High Temperature Filters may contain either ceramic or silicone sealant. As silicone sealant filters may release silicone gas during usage, for sterilization,filling, film coating and other similar processes, ceramic sealant filters are recommended.

Cambridge High Temperature Filters may contain either ceramic or silicone sealant. As silicone sealant filters may release silicone gas during usage, for sterilization,filling, film coating and other similar processes, ceramic sealant filters are recommended.

Revamping Of Filling Machine ⇓

Revamping Of Filling Machine

This Multi head Unit is specially designed to be integrated with filling system, hence provides opportunity to upgrade the filling system with servo mechanism for precise filling without modifying existing area layout.

This Multi head Unit is specially designed to be integrated with filling system, hence provides opportunity to upgrade the filling system with servo mechanism for precise filling without modifying existing area layout.

- Solution to problems inherent to filling stations,aiming at wiping out issues related to product,viscosity,drop splash etc.

- Individual control of filling pumps.

- Tool less change over filling syringes.

- Precision of filling +/- 0.1%.

- Easily integrated to any make of existing filling machine.

- Available in various number of filling head depending upon existing filling machine speed.

- Upgrading of filling to have precise filling without any area modification.

- Trouble free system hence gives freedom for mechanical setting of fill volume. Fine setting can be done through touch screen.

- Better filling hence less wastage and more yield.

- No mechanical spare consumable.